Results of the Floating Wind Challenge 2025 (updated on 07/16/25):

- The Eolita team won the prize for best structural integrity and third prize for best report. Find out more

- The Taka4Ventis team won the prize for best anchors and moorings. Find out more

Congratulations to both ENSTA teams!

The Floating Wind Challenge is a student competition that aims to stimulate potential future engineers in the search for innovative solutions for designing the wind floats of tomorrow. The goal is to build a small-scale float for a 400W wind turbine while considering the cost and feasibility of such a solution at full scale for a 15MW wind turbine.

Blandine Duprat, a final-year student on the general engineering program at ENSTA Paris, and Raed Rezgui, a member of the Brest team training as a marine renewable energy expert, answer our questions.

How is the project going for your teams?

Blandine Duprat: Our “EoliTA” team consists of seven students. It was created as part of the tutored project for the “Engineering and Design” profile in the third year.

Supervised by Luc Pastur, a lecturer and researcher at the Mechanical Engineering Unit (UME), and Côme Reynaud, an ENSTA graduate and engineer at Eiffage Métal, we launched the project in October 2024.

After a phase of collective reflection on the concept of the float we wanted to design, we divided up the various studies necessary for the successful completion of the project (static and dynamic calculations, market research, choice of materials for our concept, etc.). At the same time, we produced a presentation sheet for our project, which enabled us to qualify for the competition and obtain €1,000 in funding for the construction of our float.

Once the theoretical studies were complete, we all devoted our free time to building the float with the help of Lahcène Cerfa, a technician at the UME, who assisted with the welding. At the end of our efforts, we submitted a detailed report on our work and our thoughts, along with a video of the tank tests that we were fortunate enough to carry out at EDF Lab Chatou. After receiving constructive feedback from the competition, we are currently finalizing work on the structure so that we can test the installation in real conditions ahead of the competition.

And what about Taka 4 Ventis?

Raed Rezgui: This year, the Brest team “Taka 4 Ventis” is made up of four members. Tasks were divided based on each person's skills and the four main areas of the project:

- electronics,

- mechanics and hydrodynamics,

- structure,

- and economic analysis.

The first key step was the submission of the abstract on January 17, which allowed us to pass the pre-selection phase. We were selected as one of the seven finalist teams out of 20, thus receiving €1,000 in funding to build our prototype.

After the results were announced, the construction phase took place between February and early May. We finalized the structure, then wrote and submitted the technical report summarizing the various aspects of the project.

We are now preparing for the final stages, which will take place on July 8 and 9 in Zeebrugge.

The entire project has been very educational, both in terms of project management and from a technical standpoint: we have acquired practical skills in the challenges of marine renewable energy (MRE), particularly offshore wind turbines and real-world testing. The experience has enabled us to work as a team and collectively tackle, at our level, the technological challenges of the offshore wind turbine sector.

Have you been able to test your prototype?

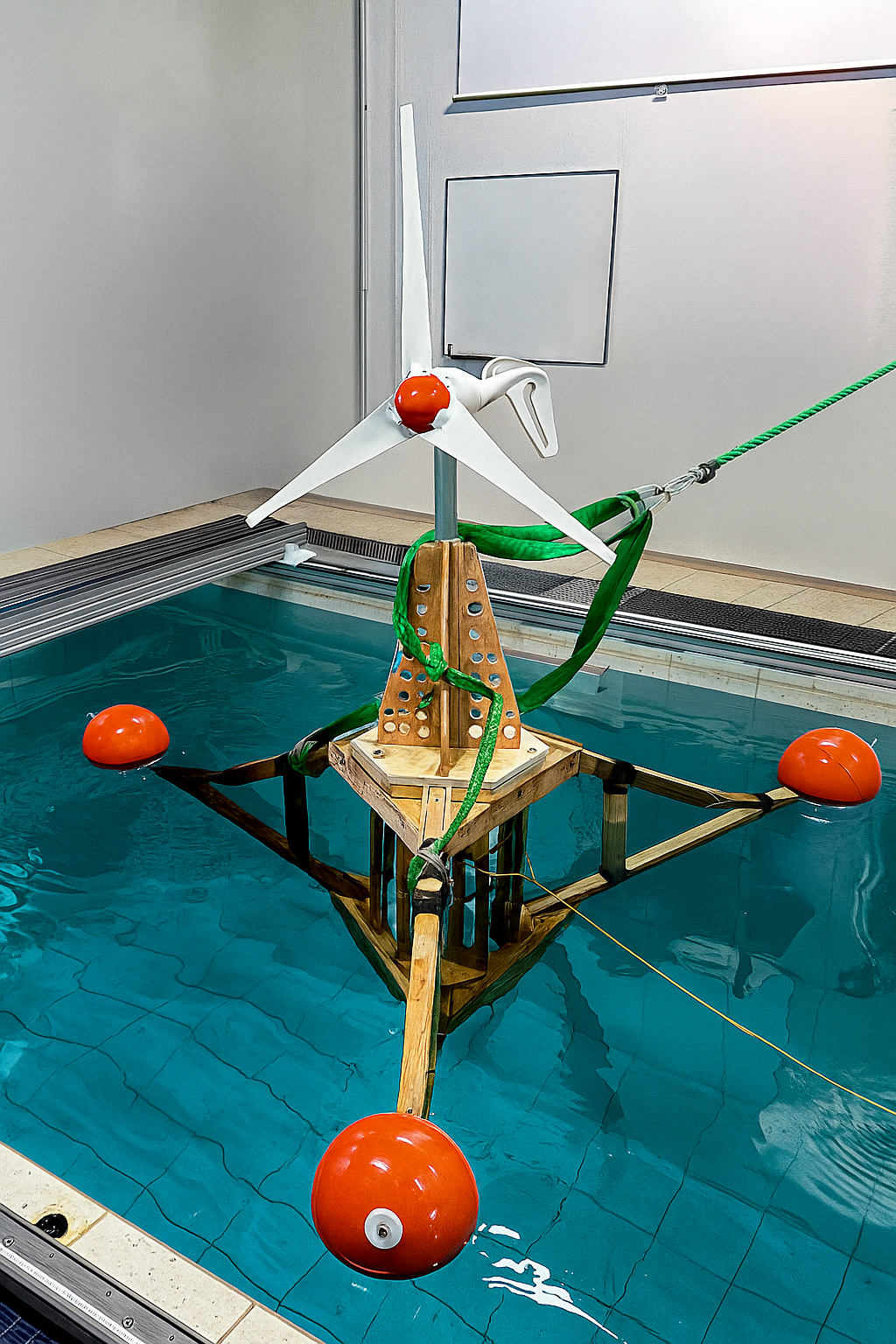

Blandine Duprat: Thanks to the support of EDF Renewables and EDF Lab Chatou, we had the opportunity to test our float in EDF's wave basin in Chatou.

This day was a key step in the experimental validation of our concept. It allowed us to observe the dynamic behavior of our prototype under simulated conditions, adjust certain technical parameters, and benefit from the feedback of offshore wind specialists present on site.

We also had the opportunity to exchange ideas with other participating teams, which led to a mutual enrichment of technical and conceptual approaches.

Raed Rezgui: Unfortunately, the sea trials initially planned at Ifremer could not be carried out due to their teams' heavy workload. We therefore carried out our experimental trials in the ENSTA pool in Brest.

These tests focused mainly on stability, buoyancy (with a deliberate 45° tilt), and measuring the natural period in pitching (editor's note: the effect of waves). All the tests were successful: the structure demonstrated excellent stability and performed as expected.

Did you encounter any difficulties during the project?

Blandine Duprat: The first difficulty we encountered was starting the project from scratch, as we are the first team from the former ENSTA Paris to participate. Côme Reynaud's experience in designing offshore structures was a great help in getting the project off the ground. In addition, reconciling our schedules during our final internship period at the end of the project was not easy, but we are now in the home stretch and are confident and motivated to deliver a functional float for the final in Belgium.

Raed Rezgui: One of the biggest challenges we faced was the small size of our team (only four members), which made it particularly difficult to divide up the many tasks. We had to work under pressure, alongside our studies and exams, which meant putting in many hours of work at night to meet the deadlines.

How do you see the FWC 2025 challenge?

Blandine Duprat: We are looking forward to participating in the final of the competition. This week promises to be very rewarding, both on a personal and technical level. Six members of the team will be present. We are eager to meet the other participants and present our work to professionals from the offshore energy industry.

Raed Rezgui: We are extremely enthusiastic and have high ambitions! We will all be in Zeebrugge at the beginning of July, ready to take up the challenge.

I would like to mention the support of Mr. Marc Le Boulluec, one of our teachers who works at Ifremer, without whom this project would not have been possible. He has supported us from the beginning and we are very grateful to him.